A specialised gantry leg can be made to suit a specific installation at hand, this leg must be made prior to the installation and ordered by the assessor during the assessment of the installation. This gantry leg is fixed to the wall following the same fixing guidelines as above, but also includes floor fixings, see the brief explanation for floor fixings below:

Concrete:

1. To fix the gantry to concrete, four holes must be drilled into the concrete using a 15mm drill bit to a depth of 80mm.

2. Insert the 14×75 Rawl plugs into the concrete floor.

3. Mark out the correct fixing locations on the gantry feet to ensure that the holes will align.

4. Drill the gantry feet to a diameter of 13mm.

5. Secure the feet into the concrete using the 12.0x70mm coach bolts.

Timber:

1. To fix the gantry to timber, the four holes must be drilled into the timber using a 10mm drill bit to a depth of 70mm

2. Mark out the correct fixing locations on the gantry feet to ensure that the holes will align.

3. Drill the gantry feet to a diameter of 13mm.

4. Secure the feet into the timber using the 12.0x70mm coach bolts.

5. Note: the hole positions must align with the joists in the timber floor for a secure fixing.

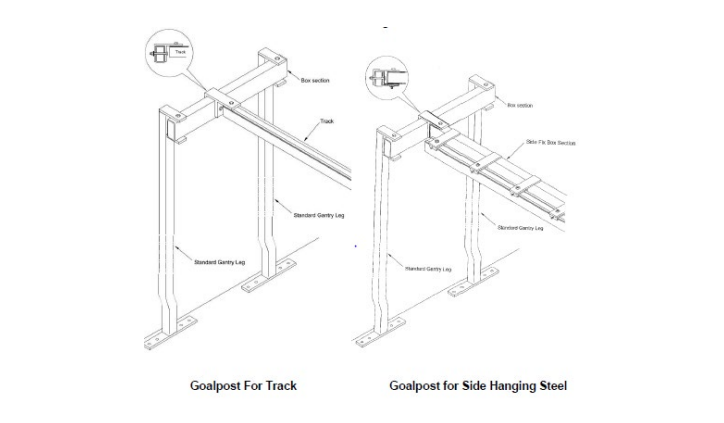

The only other variance being that the foot and head of the gantry is fixed and allows a steel box section to be fitted. Below are examples of specialist gantry fixings that are possible.

The goalpost fixing method is designed to avoid obstacles such as doorways and windows. The specialist gantry leg is typically used to attach side hanging steel box section to allow additional spanning distances for the ceiling track.