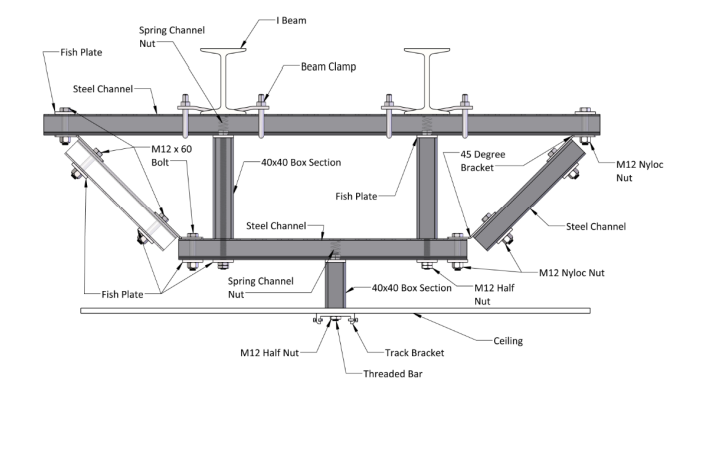

When fixing the ceiling track system using the above fixing methods (beam clamps, window brackets and flange clamps), lateral support will be required when the fixing height from the beams to the ceiling exceed 500mm. Follow the guidance below for the correct fixing method.

1. A piece of steel channel must be cut to a suitable length, this must incorporate gap between the two beams, and allow additional length to fix the lateral supports at both ends of the channel.

2. Two spring channel nuts must be positioned within the steel channel, located directly below the beam positions.

3. Fix the steel channel to the beams following a suitable fixing method from section 4.0.

4. Two pieces of threaded bar must be cut to a suitable length, around 120mm from the ceiling height.

5. Insert the threaded bars into the spring channel nuts, Loctite 270 can be used for additional security.

6. Two pieces of box section must be cut to length, this must be shorter than the threaded bar, allowing enough space for the steel channel and fixings below.

7. Place the box sections onto the two threaded bars.

8. A piece of steel channel must be cut to length, this must span the width of the two box sections and allow additional length for two 45° brackets to be fixed either end.

9. Insert a spring channel nut into the steel channel and locate at the centre of the steel channel.

10. Place the steel channel onto the threaded bar and secure in place using two half nuts and a fish plate at either end.

11. Any excess threaded bar can be cut for tidy installation.

12. Onto both ends of the lower steel channel, the 45° bracket must be fixed.

13. The brackets can be fixed using an M12x60 bolt, and a fish plate and two half nuts on either side. Repeat this for both brackets on either side of the steel channel.

14. Two more 45° brackets must be fixed to the upper steel channel.

15. The brackets can be fixed using an M12x60 bolt, and a fish plate and two half nuts on either side. Repeat this for both brackets on either side of the steel channel.

16. Fix the steel channel to the brackets using M12x60 bolts and two half nuts. The steel channel should be at a 45° angle. Ensure to repeat this for both sides of the box assembly. See the images below for reference.

17. A piece of threaded bar can now be cut to length to reach from the spring channel nut to the false ceiling.

18. Insert the threaded bar into the spring channel washer. Lock in place with a fish plate up against the steel channel and a half nut to secure.

19. With the threaded bar protruding through the false ceiling, a 40×40 box section template can be cut out of the tile.

20. A piece of 40×40 box section must be cut to length to be placed onto the threaded bar and down to the ceiling height.

21. Thread the track bracket, either a single 55mm threaded hole or a double 110mm threaded hole (depending on the bracket requirement with the track) onto the threaded bar and up against the box section locking in place with a half nut.

22. Repeat this process for each track bracket to complete track bracket installation