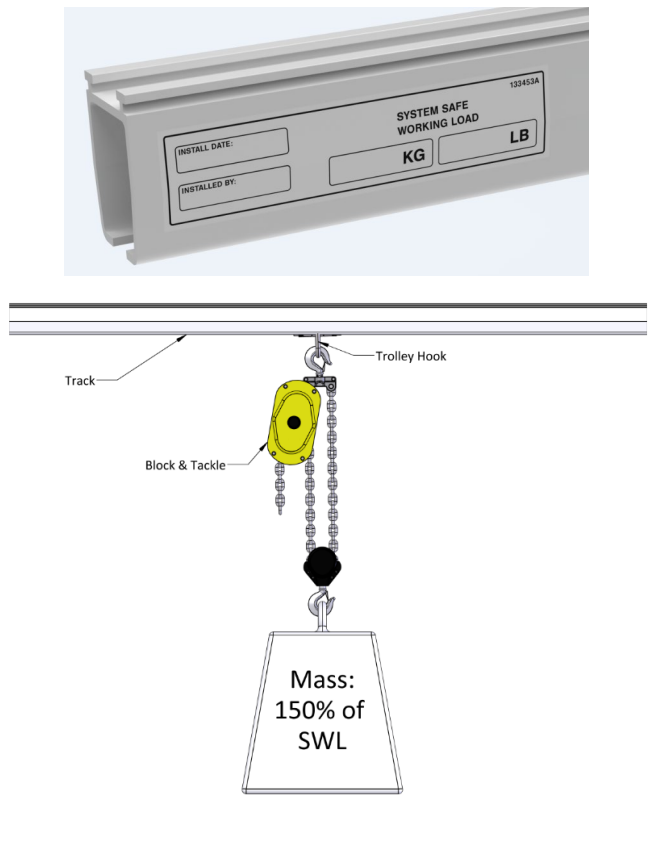

Once the full installation of the ceiling track system is complete, load testing is an essential final step to prove the system is installed correctly and safely.

Depending on the safe working load (SWL) the track is labelled as, this will be the SWL of the hoist installed. The track must be loaded with 150% of the SWL to ensure that the system is safe for use.

The hoist should not be used to raise this load as it is not permitted to do so. Follow the procedure below to safely load test the track system.

1. Insert a trolley set into the track system.

2. Attach a block and tackle to the trolley.

3. A weight stack/trolley should be placed directly below the block and tackle and attached.

4. Raise the load off the floor, no higher than 300mm.

5. Traverse the load across the full track system, from one end stop to the other.

6. Where h-systems are installed, traverse the hoist along the moving track as well as traversing the moving track along the parallel tracks, ensure that the load has been placed at both ends of the moving track to test the moving track traversing ability as well as the structural integrity of the installation of the parallel track.

7. Where transition gates are installed, ensure to test the transition of the load between at the gate to ensure that it is smooth and functional.

8. Where turntables are installed, ensure to test the transition of the load between the turntable and the fixed track, the transition should be smooth and functional.

9. Test the turntable is able to rotate smoothly with the track system SWL. This is the hoist SWL.

10. For a full track system that includes track bends, turntables, and straight track, the load should be traversed around the full system to ensure that the structural integrity is secure.

11. Once completing the full testing procedure, remove the load, block tackle, and trolley from the system.

12. The system fixings should be inspected for any damage that causes concern to safety and function. E.g. Cracks and deformation.

See the table below for a list of safe working loads and their test loads

|

System SWL |

System SWL |

|

130kg |

195kg |

|

160kg |

240kg |

|

200kg |

300kg |

|

272kg |

408kg |

|

380kg |

570kg |

Testing a wall-to-wall track system will become an issue due to the inaccessibility of the track. While installing the hoist, the test trolley should also be inserted at the same time. From here the test procedure above can be completed. At the end of the testing procedure, the track must be removed from one wall bracket fixing to allow the trolley to be removed, ensure to fix the track back onto the wall bracket once completed. Following this, the track must be re-loaded to the hoist SWL by attaching the load to the hoist and traversing along the track system.

When the load test is complete, the test engineer must fill out the load test certificate. Ensure to correctly fill out the details required on the sheet.

When completing the load test on the ceiling track system, the client should be present, both the test engineer and the client must both sign the load test certificate to confirm the load test occurred.

Once this is all complete, a load test sticker must be applied to the track, this sticker will confirm that the track has been load tested to 150% the SWL of the system, it will also require the date and test engineer signature to be written.

If at any point in the future the track system is used for a higher rated hoist, the track system must be retested to the requirements of the table above.

The track loading of 150% is required following the requirements of section 7.5 of BS EN ISO 10535:2006.